How to Fix an iPhone 11 Pro That Won't Turn On

Today we will share how to fix an iPhone 11 Pro that won’t turn on.

Step 1: Disassemble and test

Remove the two pentalobe screws at the bottom edge and lift the screen.

After the screen is lifted, take the shielding covers off, disconnect the battery, and remove the screen.

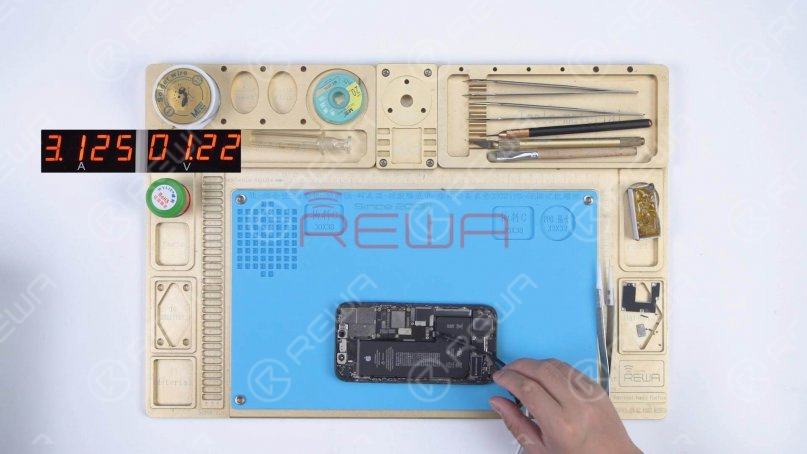

Connect the motherboard with the Power Cable. The ammeter shows a large current of 3.1A.

Detach the motherboard and connect the motherboard with the Power Cable again. The ammeter still shows a large current of 3.1A.

It indicates that the large current has nothing to do with other flex cables. The fault is on the motherboard.

Step 2: Run diode mode measurement

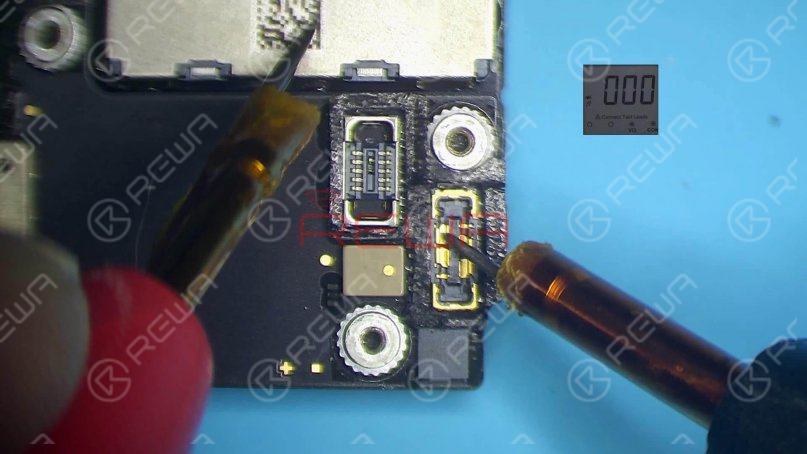

Run diode mode measurement of pin 1 on the J7010 of the battery connector. The diode value is 0 which indicates that the main power supply circuit is shorted to the ground.

Since the circuit simultaneously supplies power for the logic board and signal board, we need to separate the motherboard to locate the fault.

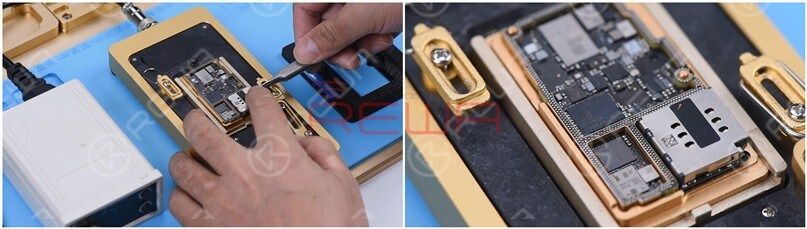

Step 3: Motherboard separation

Remove foam on the motherboard. Then heat the back of the motherboard with Hot Air Gun at 240℃ to remove the shielding paper.

Put the motherboard on the Heating Platform. To make it easier to remove the logic board after separation, drive a screw on the logic board.

Set the temperature of the Heating Platform to 185℃.

Clamp the screw to remove the logic board when the temperature has risen to 185℃. Lastly, remove the signal board.

Step 4: Run diode mode measurement again

Run diode mode measurement of pin 286 on the signal board. The diode value is 0. It suggests that the main power supply of the signal board is shorted to the ground.

Measure pin 286 on the logic board. The diode value is 363 which means the logic board is normal.

Open the bitmap. We can see there are many associated components on the main power supply circuit.

Step 5: Rosin detecting to locate the fault

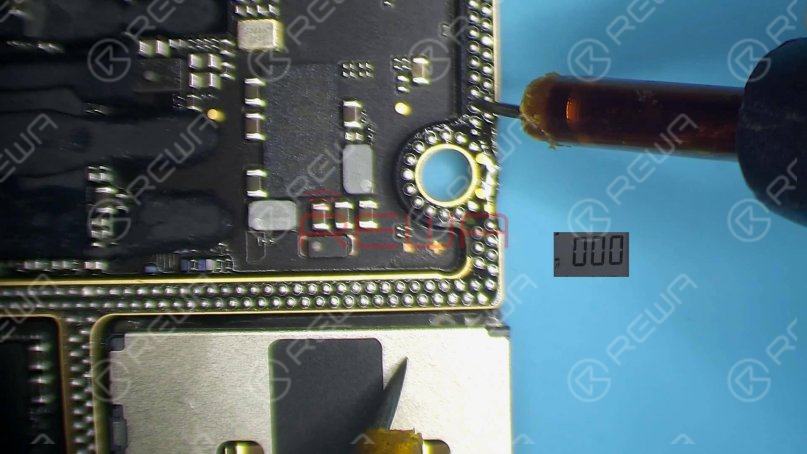

Next, we need to locate the faulty component with rosin detecting.Remove thermal grease with a Sculpture Knife. Then dip rosin with Soldering Iron at 365℃ and smoke rosin on the signal board.

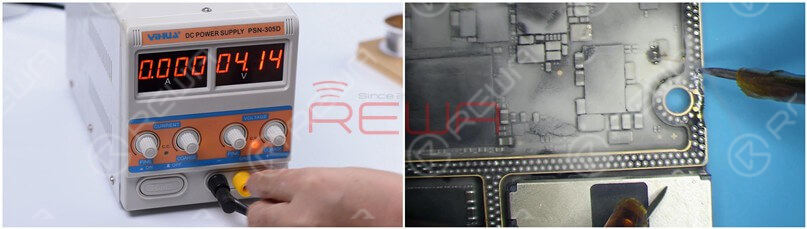

Set the direct current supply to 4.1V. Connect the positive and negative anode of the direct current supply with multimeter probes. Connect the black probe to the ground and connect the red probe to pin 286 on the signal board. We can see rosin on C1200_K has melted. It indicates that the capacitor is damaged.

Step 6: Eliminate the fault and restore the motherboard

Then we heat the damaged capacitor with Hot Air Gun at 350℃ and remove it with tweezers.

Clean rosin on the signal board with PCB Cleaner. Run a second diode mode measurement. The diode value returns to a normal value of 327.

Smear rosin with Soldering Iron and solder wick at 365℃ to remove tin on the bonding pad. Clean the signal board with PCB Cleaner.

Remove tin and clean the logic board with the same method.Attach the signal board to the Reballing Platform and put the Reballing Stencil in position. To prevent the solder paste from flowing into the motherboard crevices, insert a metal plate. Apply a layer of low-temperature Solder Paste.

Remove the Reballing Stencil and put the signal board on the Heating Platform at 185℃ to heat. After the solder balls are formed, turn the power off and cool the motherboard for 5 minutes.

Apply some Paste Flux and align the logic board with the signal board. Keep heating on the Heating Platform at 185℃. When the temperature reaches 185℃, keep heating for 1 minute.This step is to ensure that the logic board and the signal board fit closely.

Step 7: Test and assemble

Connect the motherboard with the Power Cable and short to the ground of the J7700 pin 12. The boot current becomes normal.

Put the motherboard on the phone. Connect the flex cables, screen, and battery. Because the battery is dead, plug the charging cable and the phone turns on normally.

Summary

iPhone 11 Pro won’t turn on with a large current. We found that the main power supply was shorted to the ground through measuring the battery connector. The fault was found to be on the signal board after separation. Rosin detecting showed us that C1200_K was damaged. After removing C1200_K, the fault was cleared.

For more iPhone Won't Turn On content, please read the articles below.

Fix an iPhone X that Won’t Turn On with Large Boot Current Step by Step

iPhone X Won’t Turn On Quick Fix – Thermal Imager Applied

iPhone XS Won’t Turn On – Quick Fix

How To Fix iPhone X Won’t Turn On By Board Swap

Find The Faulty Component With Rosin – iPhone 7 Plus Won’t Turn On

How to Fix iPhone X Won’t Turn on With Logic Board Repair

Fix iPhone 7 Won’t Turn On – CPU Repair

iPhone 6 Won’t Turn On Repair – PMIC Grinding and Replacing

If you want to study more, please feel free to visit our academy for repair courses.

2

0

No Comments

2

0

Share

Apr 23, 2021

ABOUT REWA

REWA is a world leading electronics repair business solutions provider who was founded in 2008 in HongKong. We are committed to delivering one-stop services covering Sourcing Solution, Technical Support Solution as well as Recycle & Resell Solution.

Sign In

Sign In

Shop

Shop

Academy

Academy